PDCA:Plan-Do-Check and Act like a pro!

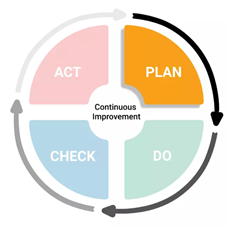

PDCA Model

The PDCA model (or Deming cycle), PLAN-DO-CHECK-ACT, is an iterative process to continually improve products/services, and people. The PLAN-DO-CHECK-ACT model includes testing solutions, analyzing results, and improving the process.

4 Steps of the PDCA

Plan

The first letter in “PCDA” means planning what needs to be done, based on the size of the project. This planning can take a lot of effort from team members. The following questions must be answered:

- What is the problem to be solved?

- What do we need to solve it?

- What resources do we have?

- What is the best solution to solve the problem using the available resources?

- What are the conditions that qualify the plan to be considered successful?

- What are the goals?

BTW, you should review the plan several times before moving on to the next step.

Why? because that’s from where you start improving, so you have to collect enough information before you decide to continue.

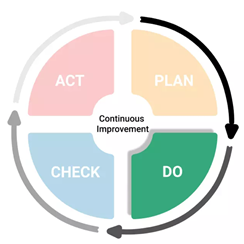

Do

Now that the plan is validated, we take action.

In this step, team members begin to apply everything that was considered in the previous step, on a small scale, and in a controlled way.

Make sure everyone knows their role and responsibilities.

Check

This is the most important step in the PDCA cycle. Much attention must be paid to the CHECK phase to avoid recurring mistakes and successfully apply continuous improvement.

If something went wrong during the process, we need to analyze it and find the root cause of the problem.

Act

After developing, applying, and verifying the plan. Now we are going to act.

If all goes well and the team has succeeded in achieving the stated objectives, we continue slowly.

The PDCA cycle is a technique for solving business problems. Finally, keep in mind that the PDCA model takes some time and may not be suitable for solving urgent problems.

What do you think? tell us!

MORE YOU KNOW, MORE YOU GROW :

Find us on LinkedIn.

Reading more? Check out other interesting topics!